Free Electrical Panel Schedule PDF Form

When it comes to managing and ensuring the safety of electrical systems within any building, the Electrical Panel Schedule plays a crucial role. This essential document serves as a detailed map, guiding electricians and maintenance personnel through each circuit in the electrical panel, including its use and the amount of load it carries. Not only does it foster a safer environment by helping to prevent overloading and potential electrical fires, but it also aids in troubleshooting electrical issues more efficiently. Moreover, for renovations or upgrades, the Electrical Panel Schedule is invaluable, offering a clear understanding of the system’s capacity and simplifying the process of adding new circuits. Therefore, understanding how to read and accurately complete this form is key for anyone involved in the building's electrical maintenance and planning.

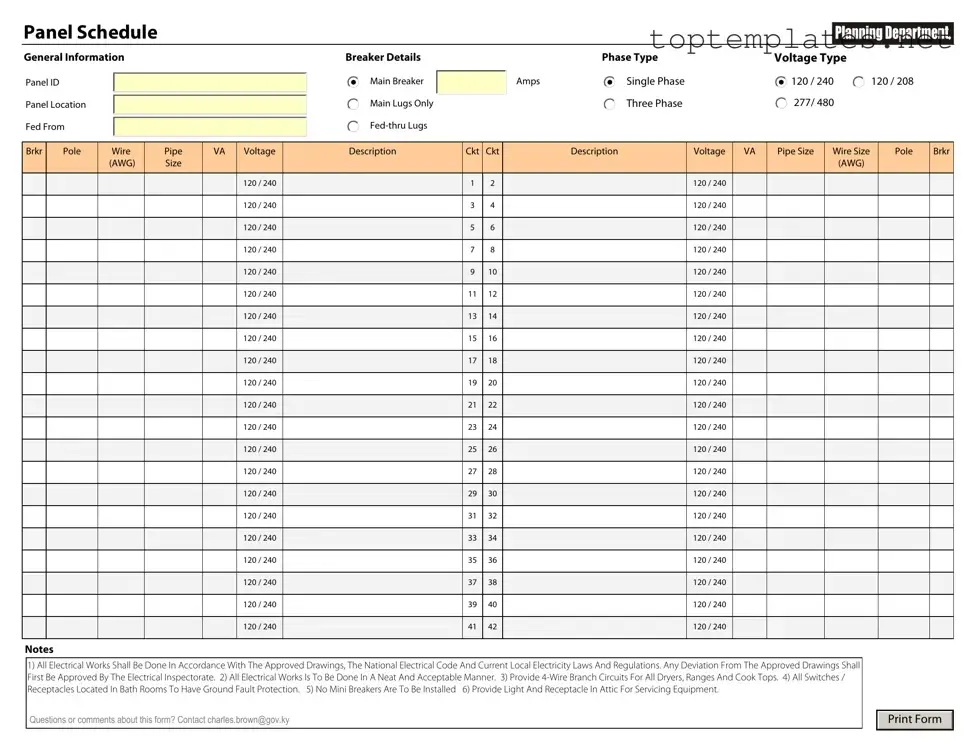

Sample - Electrical Panel Schedule Form

Panel Schedule

General Information

Panel ID

Panel Location

Fed From

Breaker Details

Main Breaker

Main Lugs Only

|

Phase Type |

Voltage Type |

|

Amps |

Single Phase |

120 / 240 |

120 / 208 |

|

Three Phase |

277/ 480 |

120 / 240 |

|

|

|

Brkr |

Pole |

Wire |

Pipe |

VA |

Voltage |

Description |

Ckt |

Ckt |

Description |

Voltage |

VA |

Pipe Size |

Wire Size |

Pole |

Brkr |

|

|

(AWG) |

Size |

|

|

|

|

|

|

|

|

|

(AWG) |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

120 / 240 |

|

1 |

2 |

|

120 / 240 |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

120 / 240 |

|

3 |

4 |

|

120 / 240 |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

120 / 240 |

|

5 |

6 |

|

120 / 240 |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

120 / 240 |

|

7 |

8 |

|

120 / 240 |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

120 / 240 |

|

9 |

10 |

|

120 / 240 |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

120 / 240 |

|

11 |

12 |

|

120 / 240 |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

120 / 240 |

|

13 |

14 |

|

120 / 240 |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

120 / 240 |

|

15 |

16 |

|

120 / 240 |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

120 / 240 |

|

17 |

18 |

|

120 / 240 |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

120 / 240 |

|

19 |

20 |

|

120 / 240 |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

120 / 240 |

|

21 |

22 |

|

120 / 240 |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

120 / 240 |

|

23 |

24 |

|

120 / 240 |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

120 / 240 |

|

25 |

26 |

|

120 / 240 |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

120 / 240 |

|

27 |

28 |

|

120 / 240 |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

120 / 240 |

|

29 |

30 |

|

120 / 240 |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

120 / 240 |

|

31 |

32 |

|

120 / 240 |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

120 / 240 |

|

33 |

34 |

|

120 / 240 |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

120 / 240 |

|

35 |

36 |

|

120 / 240 |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

120 / 240 |

|

37 |

38 |

|

120 / 240 |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

120 / 240 |

|

39 |

40 |

|

120 / 240 |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

120 / 240 |

|

41 |

42 |

|

120 / 240 |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Notes

1)All Electrical Works Shall Be Done In Accordance With The Approved Drawings, The National Electrical Code And Current Local Electricity Laws And Regulations. Any Deviation From The Approved Drawings Shall First Be Approved By The Electrical Inspectorate. 2) All Electrical Works Is To Be Done In A Neat And Acceptable Manner. 3) Provide

Receptacles Located In Bath Rooms To Have Ground Fault Protection. 5) No Mini Breakers Are To Be Installed 6) Provide Light And Receptacle In Attic For Servicing Equipment.

Questions or comments about this form? Contact charles.brown@gov.ky

Print Form

File Specs

| Fact Name | Description |

|---|---|

| Definition | An Electrical Panel Schedule is a document outlining each circuit breaker's position and purpose within an electrical panel. |

| Importance | It helps in the organization, maintenance, and troubleshooting of electrical systems, ensuring safety and efficiency. |

| Components Included | Typically lists circuit numbers, descriptions of each circuit's use, ampere ratings, and sometimes the location of outlets or fixtures. |

| Usage Scenario | Used by electricians, engineers, and maintenance personnel to identify circuits and manage electrical load distribution effectively. |

| State-specific Versions | Some states may require specific formats or details on the schedule, adhering to local building codes and regulations. |

| Governing Laws | The National Electric Code (NEC) provides guidelines, but local amendments may apply; always check current local codes. |

Steps to Filling Out Electrical Panel Schedule

Successfully completing an Electrical Panel Schedule form is crucial for electricians and electrical engineers to ensure accurate documentation of the configuration of electrical panels. It serves as a detailed map of the panel's circuits, their amperage ratings, and the rooms or appliances they power. This documentation aids in future maintenance, troubleshooting, and upgrades of the electrical system. The steps to fill out the form are straightforward but require attention to detail to avoid any potential issues.

- Gather all necessary information about the electrical panel, including the total number of circuits, the purpose of each circuit, and their respective amperage ratings.

- At the top of the form, fill in the panel's general information such as location, panel name, and number. Include also the date and who is preparing the form, to provide a clear reference point for future inquiries.

- In the designated space, record the details of each circuit. Start by numbering each circuit in the first column. It is customary to follow the physical order that the circuits appear in the panel for easy identification.

- For each circuit, specify the type of circuit in the next column. This could be lighting, outlets, or dedicated circuits for specific appliances. Use abbreviations where appropriate, but ensure they are commonly understood in the field.

- Next, fill in the amperage rating of each circuit in the corresponding column. This information is crucial for determining if the circuit is overloaded or if it has additional capacity for future needs.

- Indicate the rooms or appliances served by each circuit in the designated column. This specificity aids in quick identification of which circuits affect different parts of a building or which appliances are fed by which circuits.

- If the panel has any spare circuits, list them at the bottom of the schedule. Include potential uses for these spare circuits if already planned.

- Review the form for accuracy and completeness. Ensuring all the information is correct at this stage will prevent potential electrical issues and make any future work on the electrical panel easier.

- Once the form is complete, sign and date at the designated spot at the bottom. This official sign-off is important for accountability and record-keeping.

- Submit the form as required, either through digital upload, if applicable, or by providing a hard copy to the appropriate supervisor, project manager, or records department for official documentation.

Following these steps meticulously will guarantee that the Electrical Panel Schedule form is filled out accurately and thoroughly. This diligence ensures the safety, efficiency, and reliability of the electrical panel and its associated circuits, benefiting both current and future electrical work within the facility.

Discover More on Electrical Panel Schedule

What is an Electrical Panel Schedule Form?

An Electrical Panel Schedule Form is a document that outlines the details of an electrical panel’s circuitry. It lists each circuit connected to a panel and provides information such as circuit numbers, descriptions, and the amperage allocations. This form serves as a crucial blueprint for electricians and engineers when installing, maintaining, or troubleshooting electrical systems, ensuring that the electrical load is properly balanced across circuits.

Who should use an Electrical Panel Schedule Form?

This form is primarily used by professional electricians and electrical engineers. It is also indispensable for building managers and homeowners who are involved in constructing or renovating electrical systems. Understanding and utilizing an Electrical Panel Schedule Form can aid in preventing circuit overloads and in maintaining an efficiently functioning electrical system.

How can I obtain an Electrical Panel Schedule Form?

An Electrical Panel Schedule Form can be obtained from several sources. It is often provided by electrical contractors or can be downloaded from websites offering electrical supplies and resources. Additionally, software used for electrical design often contains templates for creating a customized Electrical Panel Schedule that meets specific needs.

What information is required to complete an Electrical Panel Schedule Form?

To complete an Electrical Panel Schedule Form, information needed includes the panel name or designation, the location of the panel, the circuits connected to the panel, and details about each circuit such as circuit number, circuit breaker type, and amperage rating. Detailed descriptions of the connected loads or devices on each circuit will also be required for accurate planning and management of the electrical load.

Can modifications be made to an Electrical Panel Schedule Form once it is filled out?

Yes, modifications can be made to an Electrical Panel Schedule Form as changes occur in the electrical system, such as when circuits are added, removed, or reassigned. It is important to keep the schedule form updated to reflect the current state of the electrical panel. Accurate and up-to-date schedules are crucial for the safety and efficiency of electrical systems, especially during maintenance or in the event of an emergency.

Common mistakes

Not double-checking the panel's name and location. Every electrical panel schedule requires the accurate naming and locating of the panel. Forgetting to specify this information can lead to confusion during maintenance or upgrades.

Misidentifying circuit numbers. Circuits are numbered for easy identification. A common mistake is misnumbering these circuits, which can complicate future troubleshooting or expansion efforts.

Incorrectly listing circuit amperages. The amperage of each circuit is critical for determining its capacity. An incorrect listing of amperage can result in overloading circuits, potentially causing outages or damage.

Overlooking the need to specify the type of load. Whether a circuit is lighting, heating, or powering appliances, specifying the type of load is essential. This oversight can affect energy management and safety protocols.

Omitting phase identification. In systems where multiple phases are used, failing to identify the phase for each circuit can lead to unbalanced loads or improper connections.

Forgetting to update the schedule after changes. Electrical setups evolve; additions or modifications are made. Failing to update the panel schedule accordingly can render the document inaccurate and unreliable.

Failing to indicate spare circuits. Spare circuits are provisioned for future use. Not marking these on the schedule misses the opportunity to plan for expansions or additions efficiently.

Mislabeling the panel type. Differentiating between main panels, subpanels, and others is fundamental. Incorrectly labeling the panel type can skew the understanding of the entire electrical system’s layout.

Ignoring breaker types. Breakers can be standard, GFCI, AFCI, etc. Not specifying these types can lead to inadequate protection or non-compliance with regional electrical codes.

Improper balance between phases. Especially in three-phase systems, ensuring an even load distribution across phases is vital for efficiency and safety. An improper balance can lead to issues such as overheating or power dips.

Additional mistakes often include:

-

Leaving the maintenance record section blank. A well-maintained record of inspections and repairs supports preventive maintenance and compliance with safety standards.

-

Using non-standard abbreviations or terms. Consistency in language and abbreviations ensures that the schedule is easily understood by all intended users.

-

Not providing a clear legend or key. A legend helps explain the symbols and abbreviations used in the schedule, making it more accessible and user-friendly.

Documents used along the form

In the architecture, electrical, and construction industries, preparation and documentation are as foundational as the structures being built. Among these critical documents, the Electrical Panel Schedule form is essential for detailing the layout and capacities of a building's electrical panel. However, to ensure comprehensive planning and legal compliance, this form is often accompanied by several other documents, each serving a unique role in the construction process.

- Electrical Load Calculation Sheet: This document is used to calculate the electrical load of a building. It plays a crucial role in determining the size and type of electrical panel needed to safely and efficiently distribute power throughout the structure.

- Wiring Diagram: A wiring diagram provides a detailed visual representation of the electrical system's layout within a building, including the wiring connections between different components. It is essential for planning the electrical installation and troubleshooting issues.

- Permit Application: Before commencing any construction or electrical work, a permit application must be filed with and approved by the local building department. This document ensures that the project complies with local codes and regulations.

- Inspection Report: After the electrical work is completed, an inspection report is issued by a certified inspector. This document verifies that the installation meets all safety standards and regulations, ensuring the safety of the building's occupants.

- Operation and Maintenance Manual (O&M): This manual provides comprehensive information on the operation, maintenance, and troubleshooting of the electrical system. It is an invaluable resource for the building's maintenance team to ensure the electrical system's longevity and reliability.

- As-Built Drawings: These drawings document the building and its systems as actually constructed, which may differ from the original design plans. They are essential for future renovations, maintenance, and troubleshooting, providing a precise reference of the building's current state.

Together, these documents form a robust foundation for the planning, execution, and maintenance of a building's electrical systems. They ensure that the project complies with laws, operates efficiently, and can be maintained effectively over its lifespan, offering peace of mind to both the builders and the occupants. A thorough understanding and proper management of these documents streamline the construction process, helping to avoid unnecessary delays and ensuring that the project meets all necessary safety standards.

Similar forms

Blueprints or Architectural Floor Plans: Similar to an electrical panel schedule, these documents provide a detailed layout, but in the context of a building's overall design. Electrical panel schedules complement this by specifying electrical circuit locations, thus ensuring that these installations align with the architectural vision.

Circuit Directory: This document is closely related to an electrical panel schedule as it also lists every circuit in a building. However, it often focuses more on labeling and identifying circuits rather than detailing the load calculations and panel capacities outlined in an electrical panel schedule.

Load Calculation Sheets: These are used to establish the electrical demand of a facility. An electrical panel schedule works in tandem with load calculation sheets by utilizing their data to allocate and balance electrical loads efficiently across the building's electric panels.

Maintenance Logs: Similar to an electrical panel schedule, maintenance logs track the history and condition of electrical systems. While a panel schedule may layout the initial setup and design requirements, maintenance logs continue the documentation through the operational life of the building, noting any changes, repairs, or updates made to the electrical system.

Dos and Don'ts

When filling out an Electrical Panel Schedule form, it is essential to ensure accuracy and completeness to maintain electrical system organization and safety. Below are seven do's and don'ts to assist in the process.

Do's

- Verify all the details before you start, including panel location and circuit numbers, to ensure you accurately reflect the system's current configuration.

- Use clear and legible handwriting if filling out the form manually to prevent misunderstandings or errors during system maintenance or upgrades.

- Include all relevant details for each circuit, such as the circuit number, amperage, and use/location, to provide a comprehensive overview of the system.

- Consult the most recent electrical diagrams and system updates to confirm the accuracy of the information being entered on the form.

- Utilize the remarks section to note any peculiarities or specifics about a circuit that may not be obvious from the standard information provided.

- Review the completed form for any errors or omissions, making any necessary corrections to ensure the form is fully accurate and up to date.

- Store the completed form in a secure and accessible location, ensuring quick access for maintenance personnel and future updates.

Don'ts

- Don't rush through the form filling process, as haste can lead to mistakes and oversights that might complicate future electrical work.

- Don't use abbreviations or initials that might not be universally understood, to avoid confusion and ensure clarity for anyone using the schedule.

- Don't leave any fields blank; if a section does not apply, mark it as "N/A" (not applicable) instead of leaving it empty to confirm that it was considered but deemed unnecessary.

- Don't ignore updates to the electrical system; ensure the form reflects the most current information by regularly reviewing and updating it as needed.

- Don't forget to include the date of the last update on the form, so users know how current the information is.

- Don't assume all users understand electrical terminology; provide clear and straightforward descriptions as much as possible.

- Don't handle the form casually. Treat it as an important document, keeping it in good condition and in an established location.

Misconceptions

When it comes to managing and documenting electrical circuits, an Electrical Panel Schedule is a vital tool. However, there are several misconceptions about this form that need clarification:

It's Only for New Installations: Many believe that an Electrical Panel Schedule is only needed for new electrical installations. This isn't true. It's also crucial for updates, maintenance, and troubleshooting of existing systems, ensuring that all modifications are correctly documented.

It's Too Complicated: Some may feel that creating an Electrical Panel Schedule is too complex. However, with the right guidance and templates, it can be a straightforward process. The form helps in organizing and making sense of electrical circuits, not complicating them.

Only Electricians Need to Understand It: While electricians are the primary users, understanding an Electrical Panel Schedule can benefit homeowners and facility managers as well. It allows them to have a better understanding of their building's electrical system, which is useful in emergencies and for general maintenance.

No Standard Format Required: There's a misconception that any format will do when creating an Electrical Panel Schedule. In reality, adhering to industry standards and local codes is crucial for ensuring safety and compliance. This ensures that the schedule is universally understood by professionals who may work on the system.

Only Necessary for Large Buildings: Another common misunderstanding is that only large buildings require an Electrical Panel Schedule. Regardless of size, any building with an electrical system can benefit from having a well-documented panel schedule. This aids in managing circuit loads and identifying circuits during repair or renovation.

Key takeaways

Filling out and using the Electrical Panel Schedule form is a critical task in ensuring the safety and efficiency of electrical systems within a building. With meticulous attention to detail and adherence to the following key points, you can ensure that your document serves its purpose effectively.

- Accuracy is paramount. When completing the form, double-check all entries for accuracy. This encompasses the panel's location, circuit numbers, and descriptions of their uses. Mistakes or inaccuracies can lead to operational issues or safety hazards.

- Reference applicable codes and standards. Electrical installations and maintenance are governed by codes and standards, which can vary by jurisdiction. Ensure that your Electrical Panel Schedule complies with these requirements to maintain safety and legality.

Include all necessary details. Besides basic information about circuits, it's important to document breaker sizes, voltage levels, and any notes that might inform future maintenance or expansion efforts.

- Update regularly. An Electrical Panel Schedule is a living document. It should be updated to reflect any changes, additions, or removals of circuits to keep it accurate over time. This practice ensures that anyone looking at the panel can understand its current state.

- Ensure clarity and readability. Use clear, legible handwriting or typeface, and avoid technical jargon unless it is widely understood by professionals who will be using the document. Clarity prevents misunderstandings and mistakes.

Consider security and accessibility. The Electrical Panel Schedule should be kept secure yet accessible to those who require it for work or emergency purposes. This may mean storing it in a locked cabinet on-site with limited key distribution or digitally with restricted access.

- Review and approval. Before implementing the Electrical Panel Schedule, have it reviewed by a qualified electrician or engineer. This extra step can help identify potential issues or oversights and ensure that the installation adheres to all relevant safety and operational standards.

By diligently applying these practices, you can ensure that your Electrical Panel Schedule serves as a reliable guide for managing and navigating the electrical infrastructure of your building. Regular reviews and updates will contribute to the longevity and safety of electrical systems, ultimately protecting property and people alike.

Common PDF Forms

Security Guard Report - This form is utilized for documenting the activities, patrols, and incidents that occur during a security officer's shift at a specific location, indicating the date and security personnel involved.

Profits or Loss From Business - Filing this form is crucial for self-employed individuals, as it affects their income tax liability and self-employment tax calculation.