Free Pre Trip Inspection Checklist PDF Form

Embarking on a journey, especially when it involves the responsibility of maneuvering a vehicle, demands meticulous preparation and a keen eye for safety. At the heart of this preparatory phase lies the Pre Trip Inspection Checklist, a comprehensive tool designed to ensure that all systems of a vehicle are in prime condition before hitting the road. This checklist serves not only as a safety protocol but also as a preventive measure against potential mechanical failures that could lead to accidents or costly repairs down the line. Covering everything from the integrity of the vehicle's tires and brakes to the functionality of its lights and signals, the checklist embraces a holistic approach to vehicle inspection. Moreover, its usage is not just confined to personal safety and vehicle maintenance; it also aligns with legal compliance, safeguarding drivers from potential violations and fines. Reflecting the significance of thorough preparation, the Pre Trip Inspection Checklist emerges as a quintessential component for anyone aiming to ensure a safe and compliant journey.

Sample - Pre Trip Inspection Checklist Form

Class A CDL

®

®

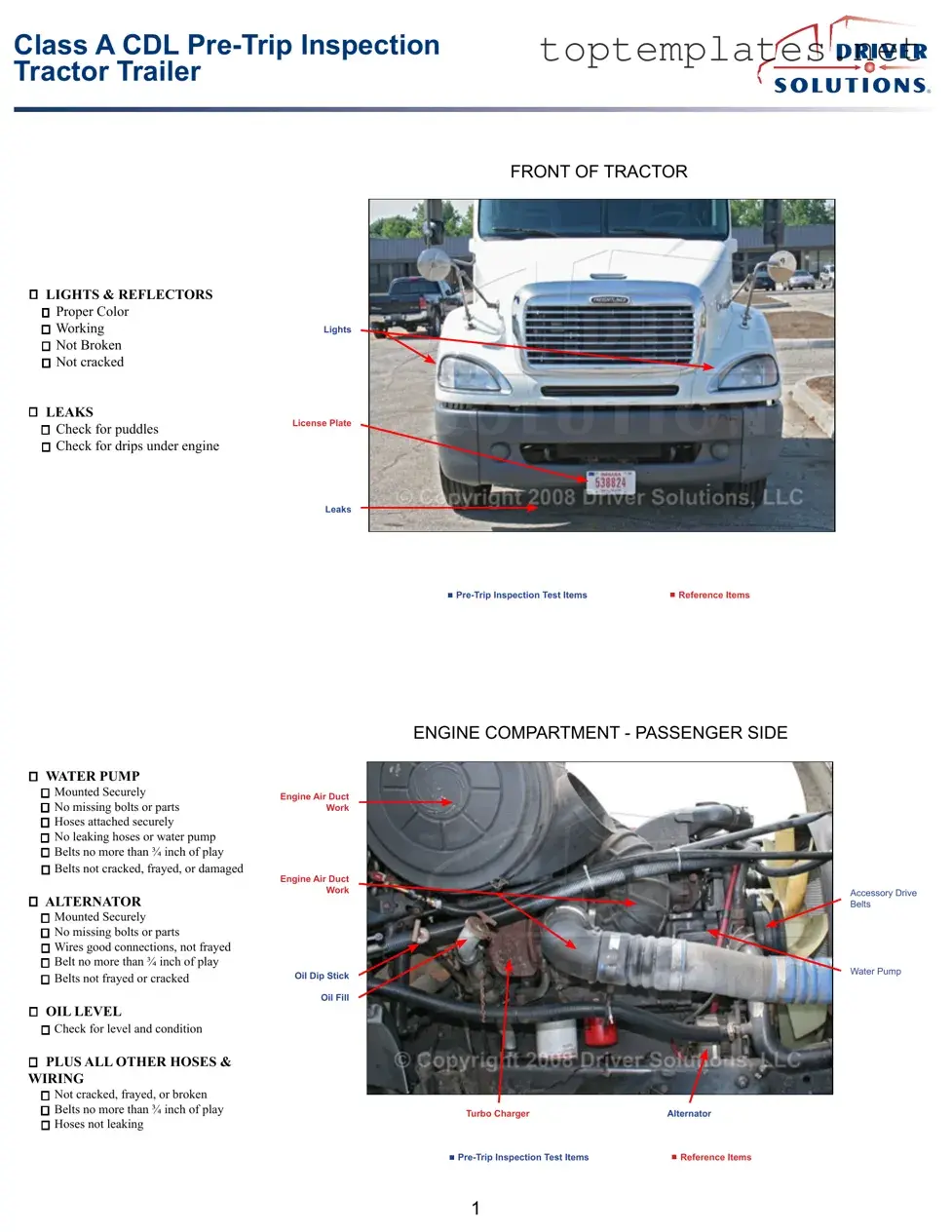

FRONT OF TRACTOR

LIGHTS & REFLECTORS o Proper Color

o Working

o Not Broken o Not cracked

LEAKS

o Check for puddles

o Check for drips under engine

Lights

License Plate

Leaks

Reference Items |

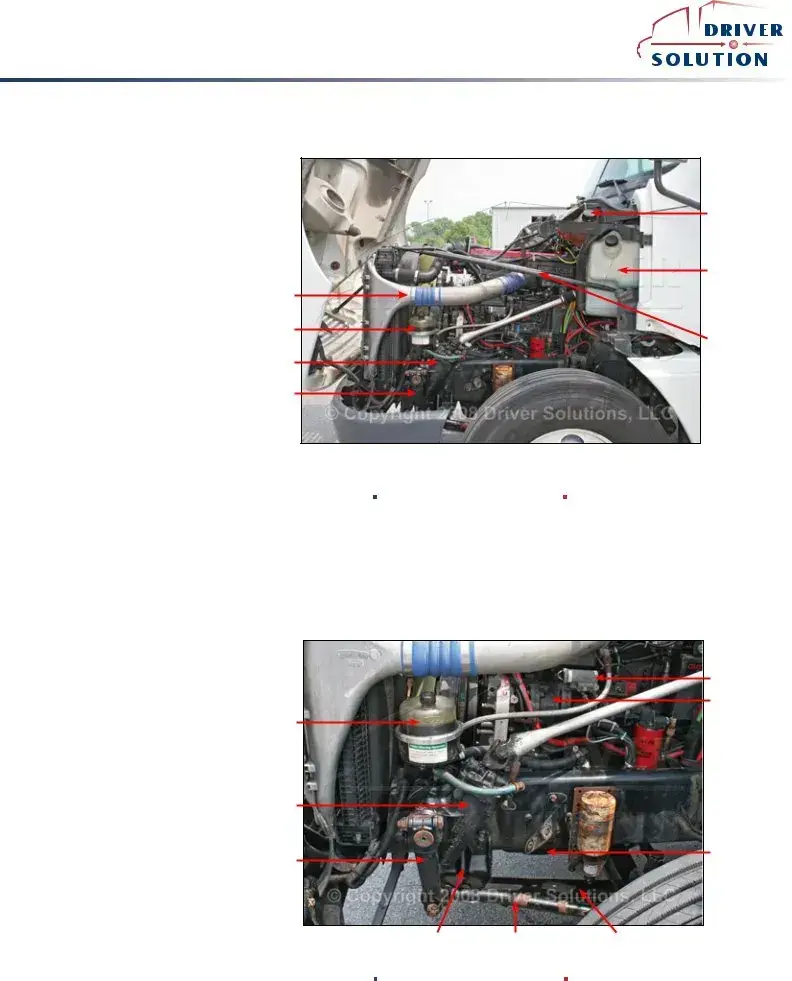

ENGINE COMPARTMENT - PASSENGER SIDE

WATER PUMP o Mounted Securely

o No missing bolts or parts o Hoses attached securely

o No leaking hoses or water pump o Belts no more than ¾ inch of play

o Belts not cracked, frayed, or damaged

ALTERNATOR

o Mounted Securely

o No missing bolts or parts

oWires good connections, not frayed

oBelt no more than ¾ inch of play

oBelts not frayed or cracked

OIL LEVEL

oCheck for level and condition

PLUS ALL OTHER HOSES & WIRING

oNot cracked, frayed, or broken

oBelts no more than ¾ inch of play o Hoses not leaking

Engine Air Duct Work

Engine Air Duct Work

Oil Dip Stick

Oil Fill

|

Accessory Drive |

|

Belts |

|

Water Pump |

Turbo Charger |

Alternator |

Reference Items |

1

Class A CDL

®

®

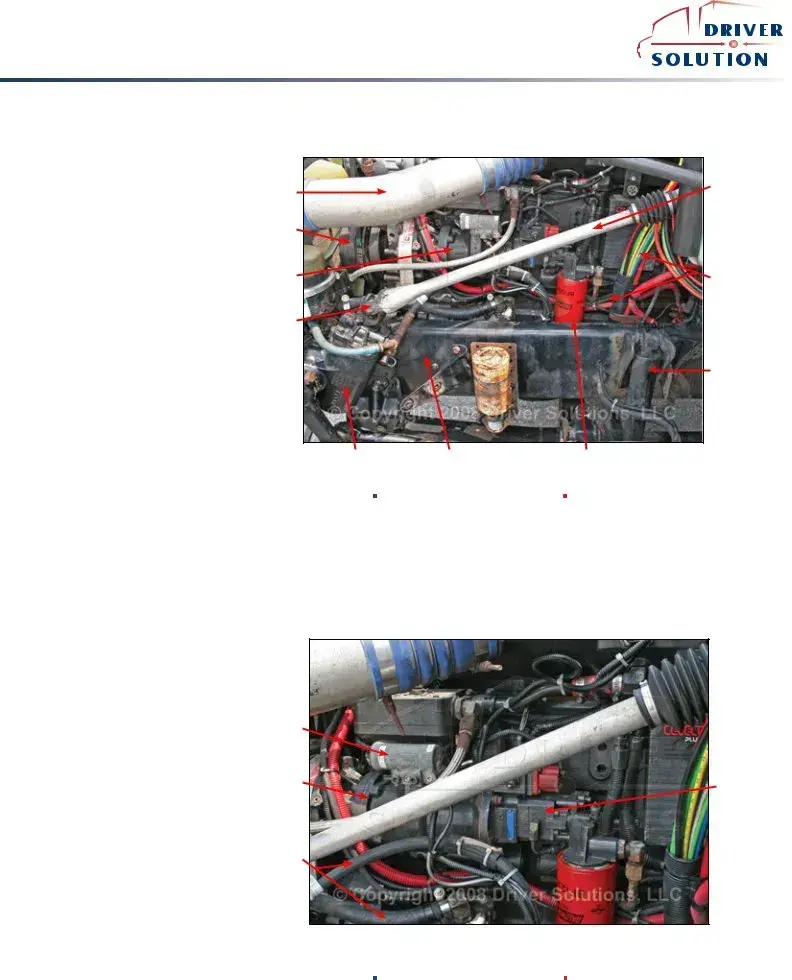

ENGINE COMPARTMENT - DRIVER SIDE

COOLANT

oCheck for level and condition

oHoses attached and not leaking

POWER STEERING RESERVOIR

oMounted properly

oHoses attached and not leaking

oCheck for level and condition

AIR COMPRESSOR

oMounted Securely

oNo missing bolts or parts

oNo air leaks at lines

oCheck if gear or belt driven

oBelt no more than ¾ inch of play

oBelts not cracked or frayed

STEERING GEAR BOX

oMounted properly

oNo missing parts, nuts or bolts o Lines and hoses not leaking or broken

|

Engine Coolant |

|

Reservoir |

|

Windsheild |

|

Washer Fluid |

|

Reservoir |

Engine Air Duct |

|

Work |

|

Power Steering |

|

Reservoir |

Radiator Brace |

|

|

Steering Gear |

|

Box |

|

Pitman Arm |

|

Reference Items |

POWER STEERING RESERVOIR |

ENGINE COMPARTMENT - DRIVER SIDE CON’T |

||

|

|

|

|

o Mounted properly |

|

|

|

o Hoses attached and not leaking |

|

|

|

o Check for level and condition |

|

|

|

AIR COMPRESSOR |

|

|

|

o Mounted Securely |

Power Steering |

|

|

o No missing bolts or parts |

|

|

|

Reservoir |

|

|

|

o No air leaks at lines |

|

|

|

o Check if gear or belt driven |

|

|

|

o Belt no more than ¾ inch of play |

|

|

|

o Belts not cracked or frayed |

|

|

|

STEERING GEAR BOX |

Steering Gear |

|

|

Box |

|

|

|

o Mounted properly |

|

|

|

o No missing parts, nuts or bolts |

|

|

|

o Lines and hoses not leaking or |

Pitman Arm |

|

|

broken |

|

|

|

|

|

|

|

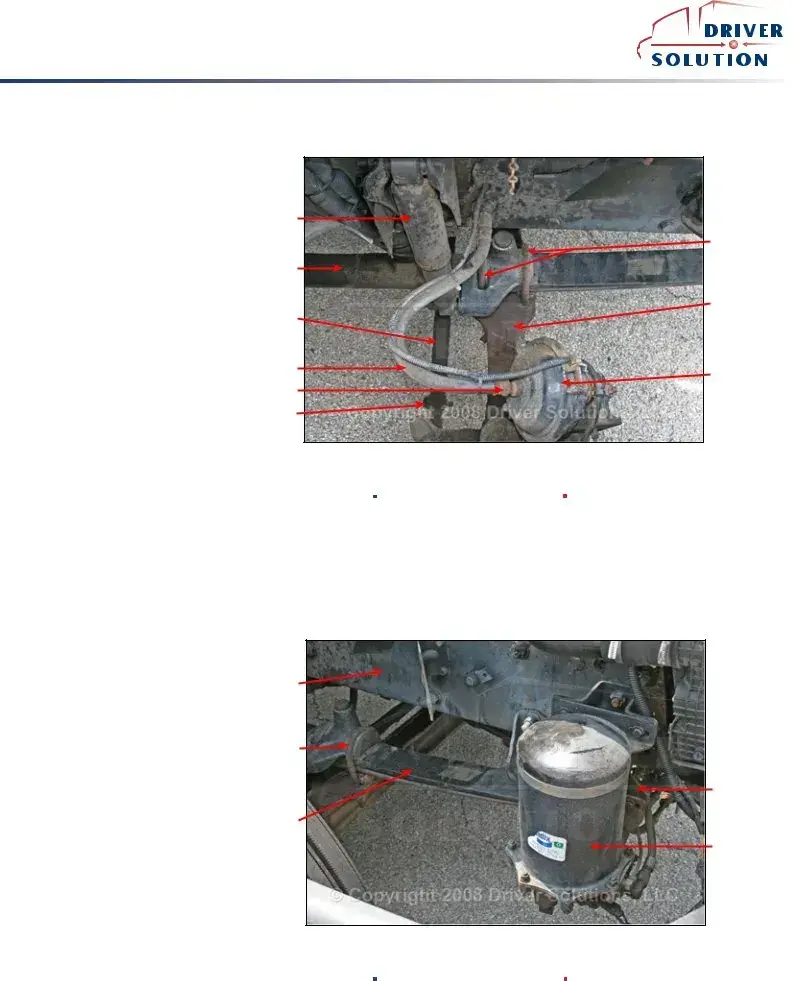

STEERING LINKAGE |

|

|

|

o Pitman arm, Drag link, Steering |

|

|

|

knuckle, Tie rods and tie rod ends |

|

|

|

o Not cracked, bent or broken |

Spring Mount |

Drag Link |

Leaf Spring |

o Castle nuts and cotter pins |

|

|

|

o Not missing and in place |

|

|

|

Reference Items |

Air Governor

Air Compressor

Engine Oil Pan

2

Class A CDL

®

®

AIR COMPRESSOR o Mounted Securely

o No missing bolts or parts o No air leaks at lines

o Check if gear or belt driven

o Belt no more than ¾ inch of play o Belts not cracked or frayed

STEERING GEAR BOX

o Mounted properly

oNo missing parts, nuts or bolts o Lines and hoses not leaking or broken

ENGINE COMPARTMENT - DRIVER SIDE CON’T

Engine Air Duct

Work

Fan Belts

Gear Driven Air

Compressor

Steering

Steering Column

Additional Hoses & Wiring

Shock Absorber

Steering Gear Box |

Frame Rail |

Fuel Filter |

Reference Items |

||

ENGINE COMPARTMENT - AIR COMPRESSOR

AIR COMPRESSOR o Mounted Securely

o No missing bolts or parts o No air leaks at lines

o Check if gear or belt driven

o Belt no more than ¾ inch of play o Belts not cracked or frayed

Air Governor

Gear Driven Air Compressor

Hoses

Fuel Pump

Reference Items |

3

Class A CDL

®

®

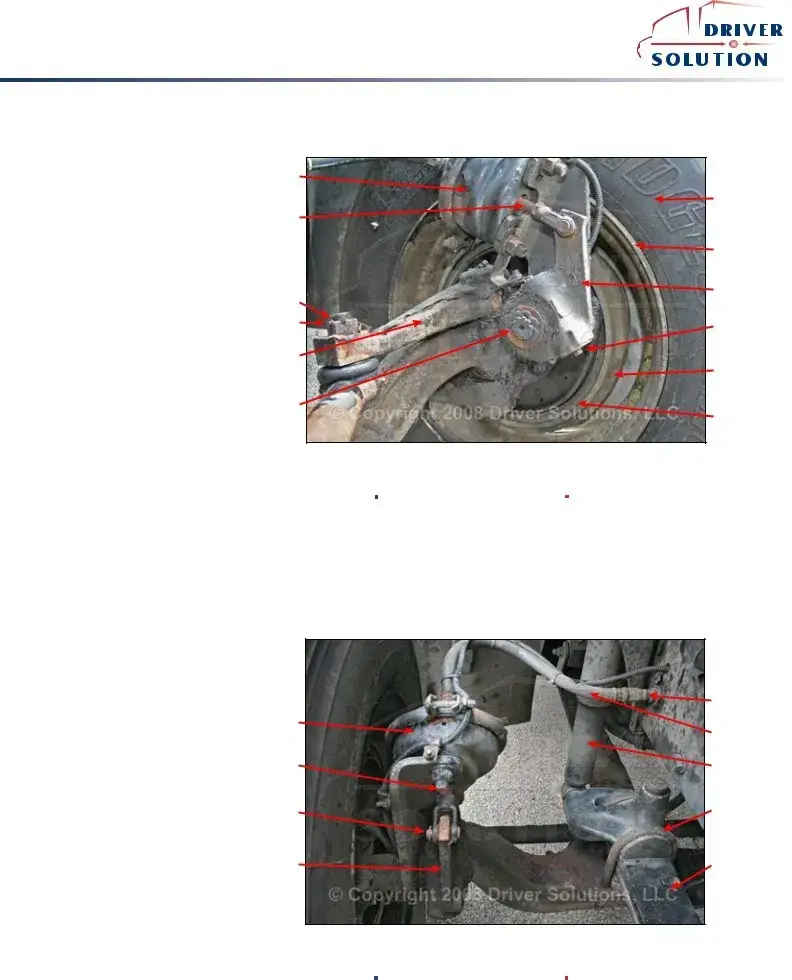

FRONT SUSPENSION

LEAF SPRINGS

o Not shifted or out of place

oNot cracked, broken or missing

SPRING MOUNTS

oMounted securely- front, back, and

oNot cracked or broken

SHOCK ABSORBER

oMounted Securely

oNot bent or dented o Not leaking

Shock Absorber

Leaf Spring

Tie Rod

Air Hose

Air LIne

Tie Rod End

Axle |

Service Brake |

Chamber |

Reference Items |

LEAF SPRINGS

o Not shifted or out of place

oNot cracked, broken or missing

SPRING MOUNTS

oMounted securely- front, back, and

oNot cracked or broken

SHOCK ABSORBER

oMounted Securely

oNot bent or dented o Not leaking

FRONT SUSPENSION CON’T

Frame Rail

Leaf Spring

Air Dryer location varies depending on model.

Located either behind the front bumper or behind the fuel tank.

Reference Items |

4

Spring Mount

Air Dryer

Class A CDL

®

®

HOSES AND LINES |

|

FRONT BRAKES |

|

|

|

||

o Mounted securely |

Service Brake |

|

|

o |

Not leaking |

|

|

o |

Not cracked or frayed |

Chamber |

|

|

Tire |

||

|

|

|

|

CHAMBER |

Push Rod |

|

|

o Mounted securely |

|

|

|

o Not dented or damaged |

|

Wheel |

|

o |

Not leaking |

|

|

SLACK ADJUSTER |

|

Slack Adjuster |

|

o |

No more than 1 inch of free play at |

Castle Nut |

|

the push rod with the brakes released. |

Cotter Pin |

Adjustment Nut |

|

o |

Not bent, broken, loose, or missing |

|

|

|

|

||

parts |

Steering |

|

|

|

|

Knuckle |

Brake Drum |

DRUMS |

|

||

|

|

||

o |

Not cracked, broken or dented |

|

|

o |

No oil leaking from inner oil seal, |

Snap Ring |

|

free of debris |

|

Brake Lining |

|

LININGS |

|

|

|

oNo cracked, broken or missing parts o Not less than ¼ inch in thickness

Reference Items |

HOSES AND LINES o Mounted securely o Not leaking

o Not cracked or frayed

CHAMBER

o Mounted securely

oNot dented or damaged

oNot leaking

SLACK ADJUSTER

oNo more than 1 inch of free play at the push rod with the brakes released.

oNot bent, broken, loose, or missing parts

DRUMS

oNot cracked, broken or dented

oNo oil leaking from inner oil seal, free of debris

LININGS

oNo cracked, broken or missing parts

oNot less than ¼ inch in thickness

FRONT BRAKES CON’T

Service Brake

Chamber

Push Rod

Clevis Pin &

Cotter Pin

Slack Adjuster

Reference Items |

Air Line

Air Hose

Shock Absorber

Spring

5

Class A CDL

®

®

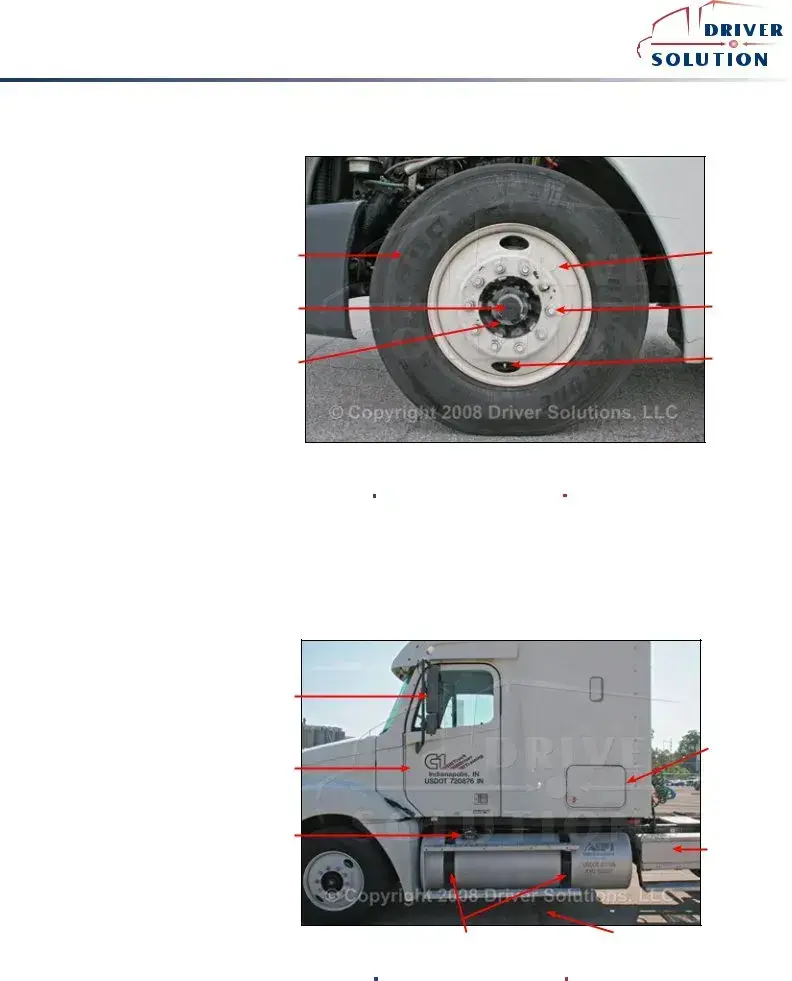

FRONT WHEEL

TIRES

oProper inflation – company or manufacturer specification

o No bulges, cuts, or retreads

o Minimum tread depth of 4/32”

RIMS

oNot bent, cracked, No welding repairs.

LUG NUTS

oNone are missing

oTight – no shinny threads, or rust trails

OUTER HUB OIL SEALS

oNot leaking, no missing bolts o Proper oil level

Tire |

Wheel |

|

Hub Oil |

Lug Nut |

|

Reservior |

||

|

||

Outer Hub |

Valve Cap |

|

Oil Seal |

|

Reference Items |

DRIVER FUEL AREA

DRIVER’S DOOR

oDoor opens and closes properly

oSeal is in good condition

DRIVER’S MIRRORS

oClean and free of obstruction

oNot cracked, broken, or damaged

oMounted securely

FUEL TANK

oMounted securely

o Not leaking

o Seal in cap OK

Mirror |

Storage |

Compartment |

Door |

Cap & Seal |

Battery Box & |

Cover |

Saddle Mounts |

Leaks |

Reference Items |

6

Class A CDL

®

®

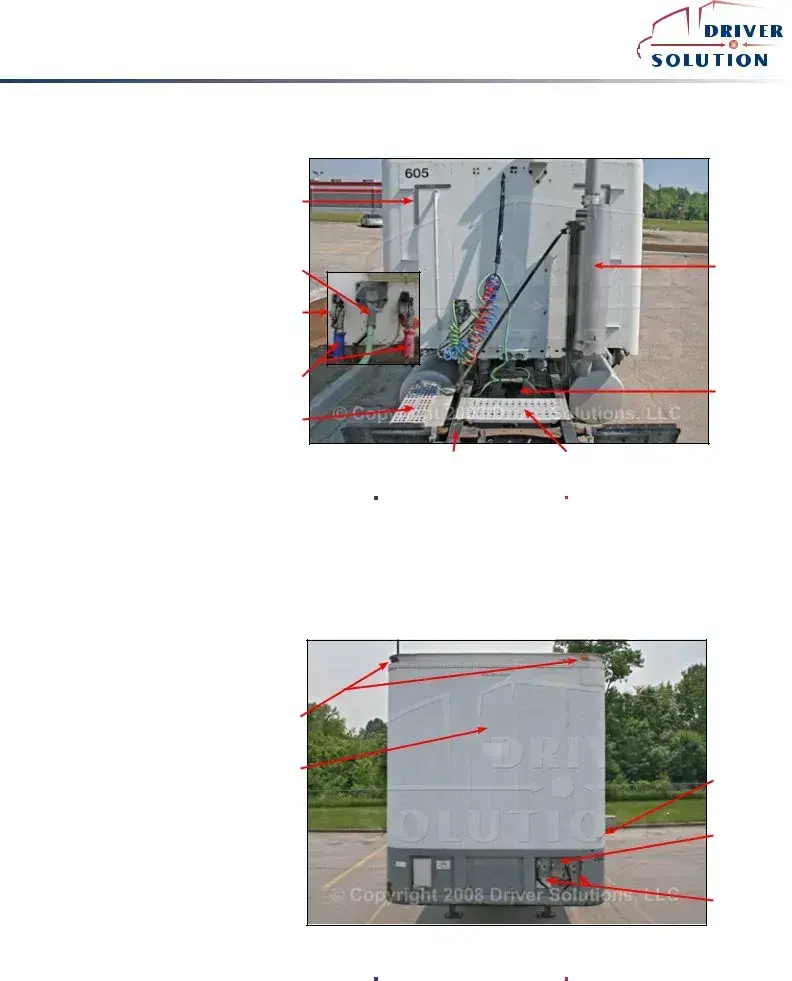

AIR LINES & ELECTRIC LINE o Not cracked, frayed, cut, or kinked o Mounted securely at the glad hands o Not leaking

BEHIND THE CAB

BATTERY BOX & BATTERIES o Box is mounted properly

o Batteries are secure in the box o Lid secure

o Connections not corroded

CATWALK

o Mounted properly

oNot, missing, or damaged

oFree of obstructions

DRIVE SHAFT

oNot bent, or damaged

oCoupling,

EXHAUST SYSTEM

oSecurely mounted

oNot dented or damaged

oNot leaking

FRAME

oNot cracked, or damaged

oNo missing bolts

oNo illegal welds

LIGHTS & REFLECTORS

oClean and working

Lights & |

|

Reflectors |

|

Electrical Line |

Exhaust |

Glad Hand |

|

Service & |

|

Emergency |

|

Airlines |

Drive Shaft |

|

|

Battery Box & |

|

Batteries |

|

Frame |

Catwalk |

Reference Items |

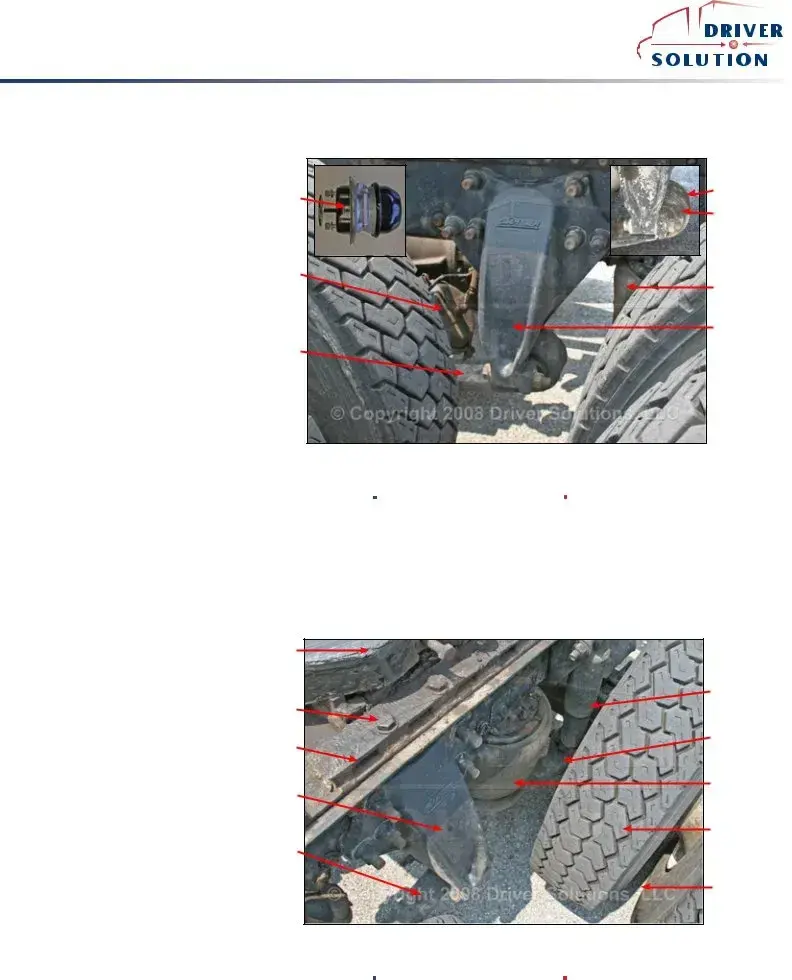

FRONT OF TRAILER

HEADER BOARD

oNo holes or missing rivets

LIGHTS & REFLECTORS

oNone broken, cracked, or missing

oWorking and proper color of amber

Lights |

Header Board |

Height Sticker

Electric Hookup

Air Line

Reference Items |

7

Class A CDL

®

®

DRIVE AXLE SUSPENSION

CONTROL ARM MOUNT o Mounted securely

o Not bent, broken or damaged

CONTROLARM

oMounted securely – front, back, and

o Not cracked, or broken

SHOCK ABSORBER

o Mounted Securely

oNot bent, dented or leaking

TORSION BAR

oMounted Securely

oNot bent, broken or damaged

AIR BAGS

oMounted Securely

o Not leaking

Spring Brake |

Torsion Bar |

|

|

Chamber |

Control Arm |

|

|

Spring Brake |

|

Chamber |

Air Bag |

|

|

|

Control Arm |

|

Mount |

Control Arm |

|

Reference Items |

DRIVE AXLE SUSPENSION CON’T & FIFTH WHEEL

CONTROL ARM MOUNT o Mounted securely

o Not bent, broken or damaged

CONTROLARM

oMounted securely – front, back, and

o Not cracked, or broken

SHOCK ABSORBER

o Mounted Securely

oNot bent, dented or leaking

TORSION BAR

oMounted Securely

oNot bent, broken or damaged

AIR BAGS

oMounted Securely

o Not leaking

Skid Plate |

|

|

Shock Absorber |

Mounting |

|

Bolts |

|

Locking |

Spring |

|

|

Pins |

|

Control Arm |

Air Bag |

|

|

Mount |

|

|

Tire |

Control Arm |

|

|

Space |

Reference Items |

8

Class A CDL

®

®

HOSES AND LINES o Mounted securely o Not leaking

o Not cracked or frayed

CHAMBER

o Mounted securely

oNot dented or damaged

oNot leaking

SLACK ADJUSTER

oNo more than 1 inch of free play at the push rod with the brakes released.

oNo bent, broken, loose, or missing parts

DRUMS

oNot cracked, broken or dented

oNo oil leaking from inner oil seal, free of debris

LININGS

oNo cracked, broken or missing parts

oNot less than ¼ inch in thickness

DRIVE BRAKES & DRIVE SHAFT

Drive Shaft

Universal Joint

Differential

Reference Items |

Air Line

Service Brake Chamber

Frame

Brake Chamber Mount

Slack Adjuster

TIRES

oProper inflation - company or manufacturer specification.

o No bulges or cuts, can have retreads o Minimum tread depth of 2/32”

RIMS

oNot bent or cracked

oNo welding repairs

LUG NUTS

oNone missing

oTight – no shinny threads, or rust trails

OUTER AXLE SEAL

oNot leaking, no missing bolts

SPACE OR SPACER

oCheck for objects between wheels

oCheck for proper spacing

Lug Nuts

Outer Axle Seal

DRIVE WHEELS

Tire

Bud Rim

Dayton Rim |

Spacer |

Reference Items |

9

Class A CDL

®

®

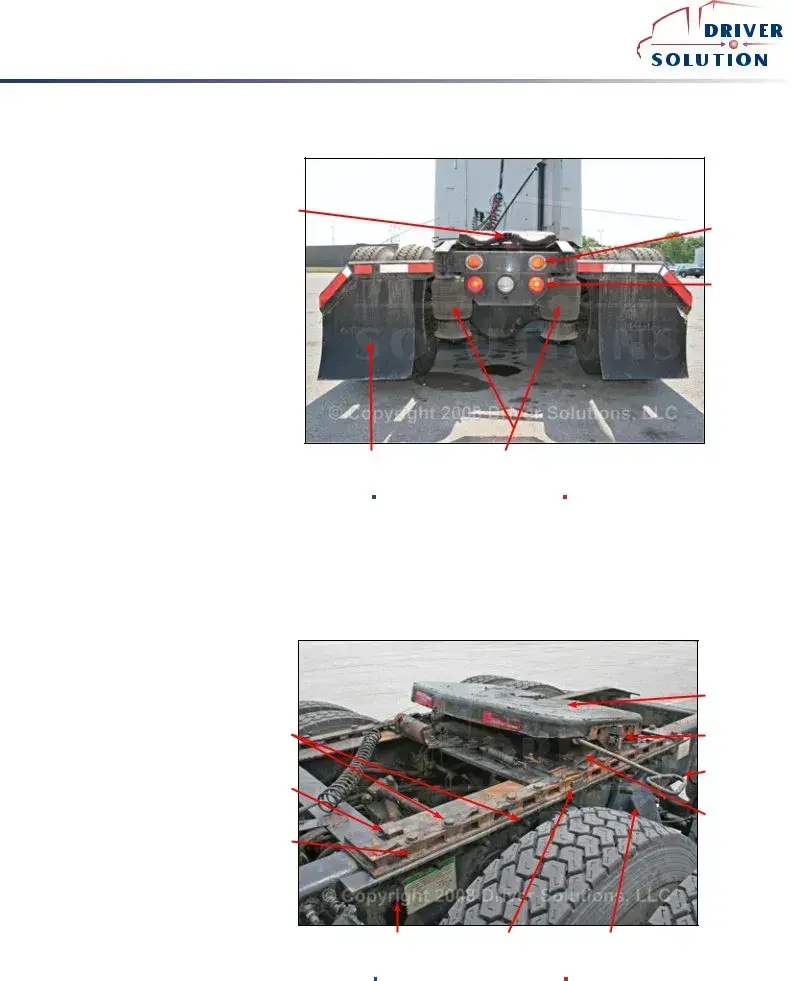

REAR OF TRACTOR

LIGHTS & REFLECTORS o Not cracked, or broken

o Working and proper color

SPLASH GUARDS

oNot missing or torn and properly mounted

Locking Jaws |

|

|

Reflectors |

|

Lights |

Splash Guard |

Air Bags |

Reference Items |

MOUNTING BOLTS

oNone missing or broken

RELEASE ARM

oNot bent, broken, or damaged

oEngaged in the lock position

LOCKING PINS

oNo missing or broken parts

oEngaged and locked

PLATFORM

oSecurely holds skid plate

oNot cracked, or broken

SKID PLATE

oMounted properly on the platform

oProperly greased

oTilting freely

Mounting Bolts

Slide Stops (all 4 corners)

COUPLING SYSTEM

Skid Plate |

Pivot Pin |

Release Arm |

Platform |

KING PIN |

Welds |

oNot broken, bent, or damaged

APRON

oNo bends or damage to visible portions

GAP

oCheck that the trailer apron is lying flat on the fifth wheel skid plate

Frame |

Slide Locking Pin |

Spring Mount |

JAWS |

Reference Items |

|

|

|

|

o Check that the locking jaws are fully |

|

|

closed around the shank of the king pin |

10 |

|

File Specs

| Fact Name | Description |

|---|---|

| Purpose | The Pre Trip Inspection Checklist form is used to ensure that a vehicle is safe and roadworthy before embarking on a trip. |

| Component Inspection | This form assesses various vehicle components including tires, brakes, lights, and steering mechanism. |

| Regulatory Basis | Federal Motor Carrier Safety Administration (FMCSA) regulations require pre-trip inspections to enhance road safety. |

| State-Specific Forms | Some states have their unique forms, aligning with FMCSA standards but tailored to state-specific requirements. |

| Governing Laws | State-specific forms are governed by respective state laws in addition to following federal guidelines. |

| Documentation | Drivers are often required to sign and date the checklist, indicating that inspection was completed and issues were noted. |

| Enforcement | Failure to complete a Pre Trip Inspection Checklist can result in fines and penalties, emphasizing the importance of compliance. |

Steps to Filling Out Pre Trip Inspection Checklist

The Pre Trip Inspection Checklist is a crucial component in the vehicle inspection process, ensuring that all safety and operational aspects of the vehicle are thoroughly checked before the journey begins. This comprehensive evaluation is designed to identify any potential issues that could jeopardize the safety of the vehicle, its occupants, and other road users. Completing this checklist is not only a proactive measure for maintaining vehicle integrity but also a regulatory requirement in many jurisdictions. The following steps will guide users through the correct procedure for filling out the Pre Trip Inspection Checklist form.

- Start by entering the date of the inspection at the top of the form to ensure that the checklist reflects the most current evaluation of the vehicle.

- Write down the vehicle identification number (VIN), license plate number, and any other unique identifier required by your organization to track the inspection back to the specific vehicle.

- Inspect the exterior of the vehicle, including tires, wheels, brakes, lights, and mirrors. For each item, mark it as satisfactory, needs repair, or not applicable (N/A) if the item does not apply to your vehicle.

- Check the interior of the vehicle, focusing on the steering mechanism, the condition of the seats and seatbelts, and the functionality of the dashboard controls. Again, mark each item as satisfactory, needs repair, or N/A.

- Test the vehicle’s emergency equipment, including hazard lights, fire extinguishers, and any additional safety gear that is required. Document the condition of each piece of equipment in the designated section on the form.

- Examine the engine compartment, checking fluid levels (oil, coolant, brake fluid, etc.), hose connections, and the general condition of the engine. Note the findings next to each checklist item.

- Perform a functionality test of the vehicle's braking system, lights (headlights, taillights, turn signals, etc.), horn, and windshield wipers. Ensure that each system is operating correctly and record the results.

- Finally, sign and date the bottom of the form to certify that the inspection has been completed to the best of your knowledge and belief. If applicable, provide your employee or identification number for record-keeping purposes.

Once the Pre Trip Inspection Checklist is fully completed, it serves as a formal record of the vehicle’s condition at the time of the inspection. It is important for drivers to address any items marked as needing repair before commencing their journey to ensure the safety and legality of their travel. The document should be stored safely as it may be required for future reference, especially in case of incidents or compliance audits.

Discover More on Pre Trip Inspection Checklist

What is a Pre Trip Inspection Checklist?

A Pre Trip Inspection Checklist is a document used by drivers before starting a journey to ensure their vehicle is in safe operating condition. The checklist helps identify any mechanical issues or safety concerns that may need attention, aiming to prevent accidents and breakdowns.

Who needs to use a Pre Trip Inspection Checklist?

Any vehicle operator, especially commercial drivers and those operating heavy or specialized vehicles, should use a Pre Trip Inspection Checklist. It's essential for ensuring compliance with safety regulations and maintaining high safety standards on the road.

What are the key components of a Pre Trip Inspection Checklist?

While the specifics can vary depending on the vehicle type, key components typically include checks for tire condition, brakes, lights and signals, steering mechanisms, mirrors, and fuels levels, among others. The checklist should also include space for documenting any defects or issues found during the inspection.

How often should the Pre Trip Inspection Checklist be completed?

It's recommended that the checklist be completed before the start of each trip. For drivers who make multiple stops or have long hauls, conducting inspections at each significant stop can help catch and address any emerging issues promptly.

What should be done if a problem is found during the pre-trip inspection?

If a problem is identified, it should be documented and reported immediately to a supervisor or maintenance team. The vehicle should not be operated until it has been properly addressed and deemed safe for use.

Is there a standard format for a Pre Trip Inspection Checklist?

While there is no one-size-fits-all format, many checklists include sections for the driver's information, vehicle details, a list of items to inspect with checkboxes, and a section for notes or comments on any defects found. Regulatory bodies or companies may provide specific formats to be followed.

Can I modify the Pre Trip Inspection Checklist to suit my needs?

Yes, you can modify the checklist to better fit specific vehicle types or company requirements. However, make sure that any modifications still comply with all relevant safety regulations and standards.

Where can I find a Pre Trip Inspection Checklist?

Pre Trip Inspection Checklists can be obtained from various sources, including online platforms, commercial driving schools, or transportation regulatory agencies. Companies may also provide their drivers with a company-specific checklist.

Common mistakes

The Pre Trip Inspection Checklist is a crucial tool designed for ensuring vehicle safety and reliability before embarking on a trip. Unfortunately, some common mistakes can hinder its effectiveness, compromising both safety and compliance. Recognizing and avoiding these errors can significantly enhance the safety and efficiency of any trip. Here are nine common missteps individuals make while completing the Pre Trip Inspection Checklist:

Skiping sections that appear irrelevant at first glance. Every section, regardless of how insignificant it might seem, plays a crucial role in vehicle safety.

Not being thorough with the inspection. A superficial check might overlook minor issues that could escalate into serious problems.

Failing to use the checklist as a guide, assuming one knows all the steps by heart. This can lead to overlooking critical inspection points.

Ignoring the importance of documenting the condition of the vehicle, both before and after the trip, which is essential for maintaining a record of vehicle health.

Overlooking the need to verify the functionality of safety equipment, which ensures protection in the event of an incident.

Forgetting to inspect the vehicle under various conditions, such as with lights on or while in motion, to ensure all systems are operational in different scenarios.

Assuming that a recently serviced vehicle does not require a thorough pre-trip inspection, neglecting the fact that issues can arise at any time.

Rushing through the checklist to save time, which often leads to missing critical issues that could prevent vehicle breakdowns.

Failing to involve a second set of eyes, whether it's a colleague or a supervisor, to verify the inspection, which can help catch mistakes or oversights.

In essence, executing the Pre Trip Inspection Checklist with diligence and attention to detail is fundamental. By circumventing these mistakes, individuals can substantially mitigate risks associated with vehicle operation, ensuring a safer journey for everyone involved. Ensuring the checklist is completed meticulously and systematically plays a pivotal role in fostering a culture of safety and responsibility.

Documents used along the form

In the realm of transportation, particularly in the commercial and trucking sectors, there are several crucial documents that accompany the Pre Trip Inspection Checklist. This checklist serves as an essential tool for ensuring that a vehicle is safe and ready for operation before it embarks on a journey. The checklist itself is a comprehensive review of the vehicle's condition, including its engine, tires, brakes, lights, and other critical components. Alongside this checklist, there are other forms and documents that are often used to maintain safety, compliance, and efficiency in transportation operations.

- Driver's Daily Log Book: This document is a detailed record maintained by the driver, noting hours of service, miles driven, and rest periods. It's a vital tool for compliance with regulatory requirements regarding drive time limits and rest periods to prevent fatigue-related incidents.

- Vehicle Maintenance Records: These records are a history of any repairs, maintenance activities, inspections, and services performed on the vehicle. They provide a timeline of vehicle upkeep and are critical for understanding the health and safety of the fleet over time.

- Cargo and Weight Tickets: For vehicles transporting goods, these tickets provide documentation of the cargo's weight. They ensure the vehicle complies with weight restrictions and helps in avoiding penalties or damages related to overloading.

- Emergency Response Information: This document outlines steps and contact information in the event of an emergency. It typically includes details on how to handle hazardous materials spills, accidents, or other urgent situations, ensuring the driver is prepared for any issues that may arise on the road.

The combination of these documents with the Pre Trip Inspection Checklist forms a robust framework for safety and compliance in the transportation industry. Each document plays a critical role in ensuring that both the vehicle and its cargo meet legal and operational standards, thus safeguarding the driver, the public, and the environment.

Similar forms

Vehicle Maintenance Log: Similarly tracks the condition and maintenance activities of a vehicle over time, ensuring its safe operation. Both documents focus on recording and identifying issues that could compromise safety or performance.

Driver’s Daily Log Book: Records the hours a driver operates a vehicle, just as a Pre-Trip Inspection Checklist ensures the vehicle is safe for operation. Both are regulatory requirements aimed at promoting road safety.

Safety Audit Checklists: Used in various industries to verify that operations comply with safety standards. Like the Pre-Trip Inspection Checklist, they aim to identify and mitigate risks before they lead to incidents.

Equipment Inspection Forms: Utilized for inspecting any type of equipment to ensure it functions correctly and safely, mirroring the purpose of a Pre-Trip Inspection Checklist but for a broader range of equipment.

Flight Pre-Check Lists: Similar to the Pre-Trip Inspection Checklist but for aircraft, these ensure all systems are go before takeoff, focusing on safety and operational integrity.

Rental Vehicle Inspection Forms: Focused on identifying any damage or issues with a vehicle before it is rented out, similar to how pre-trip inspections check for issues before a vehicle is driven.

Facility Safety Inspection Checklists: Aim to identify safety hazards within a facility. They share a common goal with the Pre-Trip Inspection Checklist of identifying and mitigating risk, though applied to stationary environments.

Incident Report Forms: Collect details following an incident or accident, often including preliminary checklists or inspections that were in place, such as a Pre-Trip Inspection, to determine if protocols were followed.

Quality Control Checklists: Used in manufacturing and production to ensure products meet certain standards before they are distributed, echoing the Pre-Trip Inspection Checklist’s role in ensuring vehicles meet safety standards.

Construction Site Safety Checklists: Aim to ensure that all safety and operational protocols are being followed on a construction site, similar to how a Pre-Trip Inspection Checklist aims to ensure a vehicle is safe and operable before it is used.

Dos and Don'ts

Performing a pre-trip inspection is a vital step for ensuring safety and compliance before hitting the road. Below are guidelines to help you fill out the Pre Trip Inspection Checklist form correctly and efficiently.

- Do review the entire form before starting. Make sure you understand each section and what information is required.

- Don't rush through the process. Taking your time to inspect each part properly can help you avoid missed items that could be crucial for safety and compliance.

- Do use clear and precise language to describe any issues or defects. Vague descriptions can lead to misunderstandings or insufficient documentation for audits.

- Don't forget to check the lighting. Inspect all lights, including headlights, brake lights, turn signals, and hazard lights, to ensure they are fully functional.

- Do ensure the tires are in good condition by checking for adequate tread depth and looking for any signs of damage or wear. Note any issues on the checklist.

- Don't overlook the brakes. Verify that the brake system is working correctly, including the parking brake. Any irregularities should be recorded and addressed immediately.

- Do make sure mirrors are well adjusted and clean. Properly positioned mirrors are critical for a safe driving experience.

- Don't ignore fluid levels. Check oil, coolant, and other fluid levels to ensure they are within recommended ranges. Report any leaks or low levels.

- Do sign and date the checklist after completing your inspection. Your signature validates that you have thoroughly inspected the vehicle and reported any issues.

Misconceptions

The Pre Trip Inspection Checklist form is subject to various misconceptions, which can lead to confusion and misinterpretation. This document is crucial for ensuring the safety and compliance of commercial vehicles before they hit the road. Below are some common misunderstandings clarified:

Only needed for long trips: A common misconception is that the Pre Trip Inspection Checklist is only necessary for long-distance journeys. In reality, it should be completed before any trip, regardless of distance, to ensure vehicle safety and compliance.

It's just a formality: Some believe that completing the checklist is just a bureaucratic formality. Contrary to this belief, it’s a critical safety measure designed to identify potential hazards or mechanical issues before they cause problems.

Drivers are solely responsible: While drivers are indeed responsible for completing the checklist, it’s a misconception that they are the only individuals involved. Fleet managers and safety officers also play key roles in reviewing and acting upon the findings.

It doesn’t need to be documented: Every inspection conducted with the checklist must be thoroughly documented. This documentation is crucial for compliance with regulations and can prove vital in the event of an incident or audit.

It’s only about the exterior: While exterior checks are essential, the checklist covers much more. It includes the interior, engine compartment, and operational capabilities of the vehicle, ensuring that all aspects are safe and functional.

Doesn’t include emergency equipment: Contrary to what some may think, the checklist also encompasses checks for necessary emergency equipment, ensuring that items such as fire extinguishers and first aid kits are accessible and in good condition.

Skipping it won’t have consequences: This is a dangerous misconception. Skipping the Pre Trip Inspection can lead to severe safety risks and legal consequences, including fines and penalties for non-compliance with transportation regulations.

It's the same for all vehicles: The belief that one checklist fits all vehicles is incorrect. Different types of vehicles may require specific checks, reflecting their unique features and compliance requirements.

Once passed, you’re good for a long time: Passing an inspection once does not ensure the vehicle is safe for an extended period. Conditions change, and mechanical issues can develop quickly, necessitating inspections before each trip to ensure ongoing safety.

Understanding and correcting these misconceptions is crucial for the safety and legality of commercial vehicle operations. By adhering to the correct procedures for the Pre Trip Inspection Checklist, operators can ensure that their vehicles are in optimal condition, thereby protecting their drivers, the public, and their business reputation.

Key takeaways

A Pre Trip Inspection Checklist is an essential tool for ensuring the safety and compliance of your vehicle before you hit the road. This checklist can help identify potential issues that might require attention, thereby preventing accidents and ensuring a smooth journey. Here are some key takeaways on how to fill out and use this form effectively:

- Detail is key: When filling out the checklist, it's important to be as detailed as possible. Each item on the list should be carefully inspected, and any issues should be noted clearly. This detailed approach helps in identifying any minor issues before they turn into major problems.

- Consistency is crucial: To ensure the safety of the vehicle over time, it's vital to carry out these inspections consistently before each trip. This consistency helps in maintaining a safe vehicle and can also assist in identifying wear and tear patterns over time.

- Training matters: Proper training on how to conduct pre-trip inspections is essential for those responsible for carrying them out. This training should cover what to look for in each item on the checklist and how to accurately assess the condition of these items.

- Follow-up is necessary: Simply filling out the checklist is not enough. Any issues identified during the inspection must be addressed promptly to ensure the vehicle is safe for the road. This may involve carrying out necessary repairs or maintenance work before the vehicle can be used.

By following these key takeaways, drivers and companies can greatly benefit from the use of a Pre Trip Inspection Checklist, ensuring that vehicles are safe and roadworthy, which in turn helps to prevent accidents and breakdowns.

Common PDF Forms

Australia Visa Application Form - Travelers are advised to check the latest travel advisories on the Department of Foreign Affairs and Trade’s Smartraveller website before embarking on international travel.

Shared Well Agreement Example - A fundamental agreement that frames the shared use and financial responsibilities tied to a communal well water supply.